Hom sapphire ua cov kauj ruam hauv peb lub Hoobkas yog raws li hauv qab no:

X-Ray NDT Crystal orientation apparatus

Ua ntej, peb siv cov cuab yeej siv lead ua kom pom kev taw qhia siv lead ua, thiab tom qab ntawd peb yuav kos cov kev taw qhia raws li cov neeg siv khoom thov

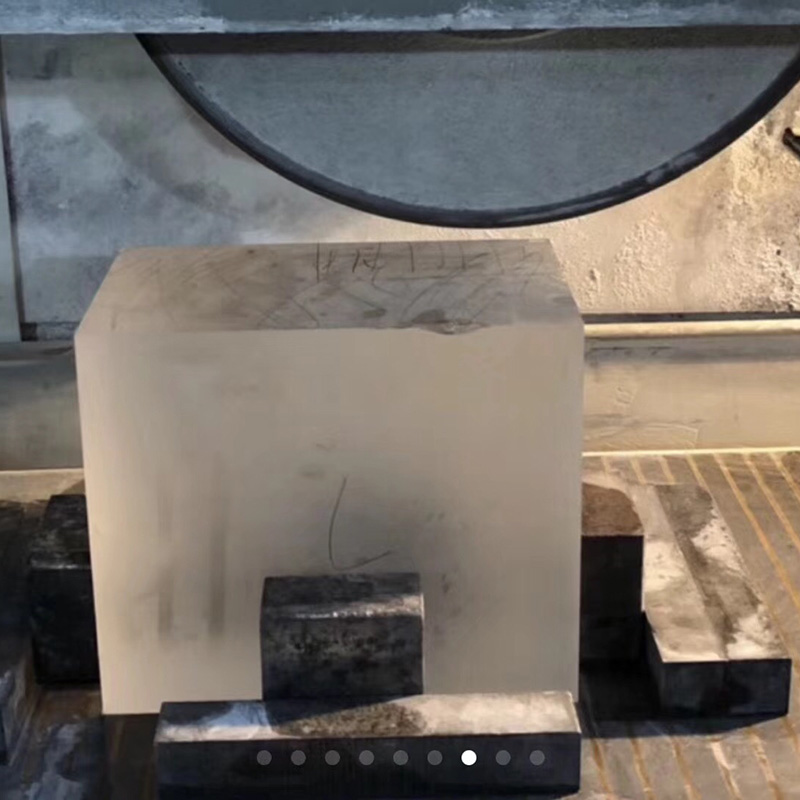

Sapphire Cib Txiav

Tom qab ntawd peb yuav hlais lub sapphire cib, lub thickness yog ze rau cov khoom tiav, tab sis cia cov txheej txheem tshem tawm cov thickness xav tau rau kev sib tsoo thiab polishing.

Rounding tshuab

Yog tias cov khoom kawg yog puag ncig, ces peb yuav hloov cov ntawv txiav square los yog puag ncig cov ntawv tiaj tus kom coj lub roundness ntawm cov khoom mus rau qib yuav tsum tau.

Chav sib tsoo

Tom qab ua tiav tag nrho cov hauj lwm yav dhau los ntawm cov duab, peb yuav ua cov khoom nto ntawm kev sib tsoo,Nyob ntawm seb qhov kev thov rau kev ua haujlwm raug, peb siv ob txoj kev sib txawv, kev sib tsoo ib leeg lossis ob sab sib tsoo.

Ib sab sib tsoo & polishing tshuab

Kev sib tsoo ib leeg yuav siv sij hawm ntev dua thiab tsim nyog rau cov khoom lag luam nrog cov kev xav tau siab saum npoo

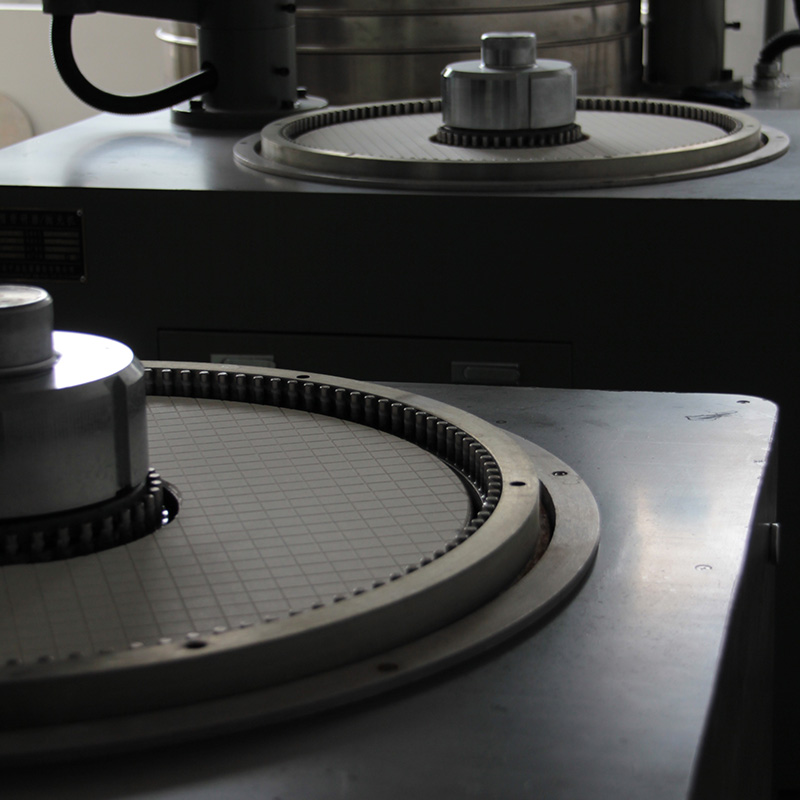

Ob tog sib tsoo & polishing tshuab

Kev sib tsoo ob sab yog nrawm dua li kev sib tsoo ib leeg, nws tuaj yeem ua tiav ob qhov sib tsoo ntawm tib lub sijhawm, thiab cov khoom sib dhos ntawm ob sab sib tsoo zoo dua li qhov sib tsoo ib leeg.

Phau ntawv Chamfering

Chamfering tuaj yeem zam qhov tsis zoo ntawm ntug kev sib tsoo ntawm cov khoom sib tsoo thiab polishing hauv cov txheej txheem machining,Nws tseem tiv thaiv cov neeg ua haujlwm los ntawm kev txiav thaum thauj khoom.

Fine sib tsoo txheej txheem workpiece

Tom qab ua tiav cov txheej txheem sib tsoo thawj zaug, nws yuav nkag mus rau qhov sib tsoo thib ob, kev sib tsoo zoo

Kev ntsuas Thickness

Thaum cov txheej txheem sib tsoo zoo tiav, peb yuav tsum ntsuas lub thickness thiab xyuas kom meej tias nws yog nyob rau hauv siab ntev ntawm cov khoom tiav. Thickness yuav tsis hloov thaum lub sij hawm polishing txheej txheem, yog li lub thickness tom qab zoo sib tsoo yuav tsum nyob rau hauv raws li qhov yuav tsum tau ntawm cov khoom tiav.

Polishing Chav

Yog tias qhov zoo ntawm cov khoom sib tsoo zoo tuaj yeem dhau qhov kev tshuaj xyuas ntawm peb cov neeg ua haujlwm txawj, ces nws nkag mus rau theem kawg ntawm kev ua, polishing. Ib yam li kev sib tsoo, peb yuav siv ob txoj kev sib txawv ntawm polishing nyob ntawm tus neeg siv khoom zoo.

Ob Chav Polishing Thiab Cov Khoom Siv Dej Ultrapure

Ob chav sided polishing tuaj yeem txo lub sijhawm xav tau rau polishing, thaum tshem tawm cov txheej txheem ntawm cov nplaum nplaum, yog li nws feem ntau yog siv rau hauv qhov kev xav tau zoo ntawm qhov chaw tsis siab, tab sis kev ua kom muaj nuj nqis loj.

Ib sab Polishing

Rau cov khoom uas muaj qhov zoo ntawm qhov yuav tsum tau ua, feem ntau yuav tsum tau ua ib sab ntawm ib sab ntawm lub tshuab polishing kom txo tau cov kev hloov pauv uas yuav tsum tau tswj nyob rau hauv cov txheej txheem ua, thiab high-precision nto hom feem ntau yuav tsum tau kho thiab ua tiav ntau zaus kom tau txais, uas tseem txiav txim siab vim li cas tus nqi ntawm cov khoom lag luam siab siab ntau dua li qhov dav dav ntawm cov khoom.

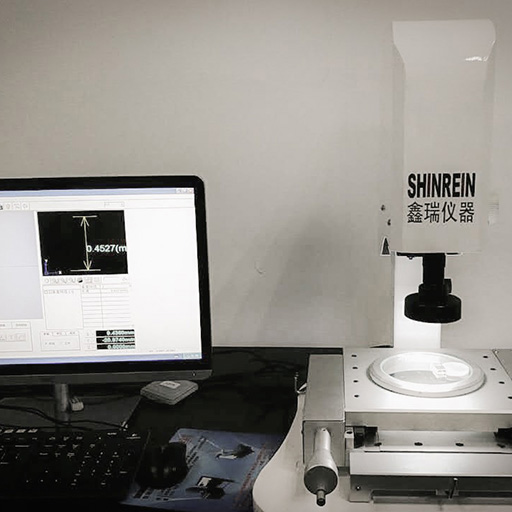

Dimensions Xyuas

Tom qab ua tiav thiab tu, cov khoom raug xa mus rau peb lub chaw soj ntsuam zoo rau kev kuaj xyuas kom paub meej tias cov khoom tiav raws li cov neeg siv khoom tsim. Tau kawg, kev xeem cov khoom tiav ntawm no tsis sawv cev rau tag nrho peb cov txheej txheem kev sim thiab kev lees paub zoo, kev kuaj khoom yuav khiav los ntawm tag nrho cov txheej txheem.,Feem ntau raws li Dimensions, roundness, parallelism, verticality, lub kaum ntse ntse, nto flatness.

Surface Quality Checking

Peb siv cov qauv tshuaj ntsuam xyuas teeb pom kev zoo thiab lub tshuab tsom iav los kuaj xyuas qhov khawb thiab qhov chaw ntawm qhov chaw ntawm cov khoom.

Nto Flatness Xyuas

Qhov chaw flatness thiab parallelism ntawm cov khoom yuav kuaj pom los ntawm kev siv laser interferometer